Project objective

I. Experimental tuning of the model parameters

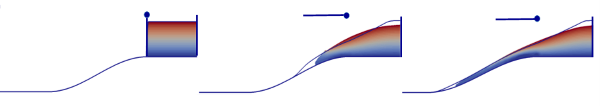

We will carry out in this project two types of experiments involving the collapse of different granular materials (sand of different granulation, mud, etc) (visco-plastic) on non-planar bottom surfaces. The laboratory tests are very important in tuning the coefficients (viscosity, internal friction coefficient and cohesion) of the mechanical model such that the whole model (depth-averaged mechanical model and its numerical approach) feets well with the experiment. All the laboratory tests are not difficult to implement, they need only a room with a fast camera and a visual acquisition system available at Simion Stoilow Institute of Mathematics of the Romanian Academy (called hereafter IMAR) laboratory of computer vision. The first experimental set up is designed to a two dimensional comparison between the experiment, the depth-averaged model and the ALE computations. The experimental setup consists of a narrow channel between plexiglass walls with a spacing of 5-10 cm (see Figure 1). The non-planar channel is 1 m long with possible inclination angles varying from horizontal up to 30°. A rectangular granular mass of thickness 10-20 cm is released from a reservoir by opening a gate. The granular material flows down on the channel, roughened by gluing a layer of the same beads on its surface. The length of the deposit is measured and the final thickness of the deposit at the back wall will be systematically recorded as well as the time at which the front stopped. The profiles of the granular mass will be measured as a function of time using a high-speed camera.

Figure 1: First experimental set up for the two-dimensional comparison of the domain occupied by the fluid/solid with the shallow model prediction.

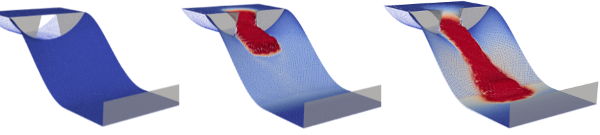

The second one is designed for three-dimensional comparison between the experiments and the depth-averaged model. We consider the flow of a visco-plastic fluid from a reservoir situated upstream, and delimited by a wall from a downstream slope (see Figure 2). The fluid in the reservoir is at rest and has, in its initial configuration, a horizontal free surface. At the initial moment the central part of the wall vanishes (the dam is broken) and the fluid starts flowing through it. As before the length of the deposit is measured and the evolution of profiles of the granular mass using a high-speed camera.

Figure 2: Second experimental set up for the three-dimensional comparison of a barrage break avallanche with the shallow model prediction.

II. User-friendly software

Finally, the end products of the project will be several software packages, implemented in C++, illustrating the nowadays successful transfer method of the scientific research results to the users via a specialized software. This user-friendly software will be constructed starting from the FreeFem++ code which was already constructed for the validation of the numerical approach. That is why the project is feasible in 18 months.

Technology Readiness Level

The project starts from TRL2 (Technology concept and/or application formulated) and develops through TRL3 (experimental proof of concept) and ends in TRL4 (technology validated in lab).